Hot Cathode Ionization Gauge

Features: Simple key operated / recordingable / FA vacuum data management /

applied to various vacuum equipment and production lines.

|

Model : IT-3DA |

Typical Specification | ||

|---|---|---|---|

|

▲Front

▲Rear

▲Gauge Head(Glass Tube) |

Measuring Range |

B-A Type |

9.9 X 10-2 to 1.0 X 10-7Pa |

|

Schultz type |

9.9 X 100 to 1.0 X 10-3Pa |

||

|

Visible Out-Put

|

Set-Point |

2 Points |

|

|

Auxiliary Function |

Hysterics value, output theory |

||

|

Rating |

AC110V 0.5A load resistance |

||

|

Satus |

AC110V 0.5A load resistance |

||

|

Sampling Cycle |

100msec |

||

|

Record Out-put |

Full range DC 0 to 5V/0 to 10V |

||

|

Service Temperature |

0 to 40ºC |

||

|

Power Voltage |

AC100~240V 50/60Hz 100VA |

||

|

Gauge head (Left figure) |

IV-55(B-A) / SC-45(Schultz) need replacement with regular |

||

|

Standard attachment |

IV-55 (B-A) or SX-45 (Schultz), all for ф15 connection, Power Cord 3m, MSG Cord 2m |

||

|

Dimension, Weight |

L350*W150*H96mm / 4.8Kgs |

||

Pulse-Ion Air Blow Gun

|

Model : HPG-7000 |

Factors |

Spec Data Description |

|

Input Voltage |

100~240Vac*50/60Hz (AC Adapter) |

|

Dimension/Weight |

30VA / 270g / W51*H185*L158mm |

|

|

Discharge Method |

High Puls AC Method |

|

|

Discharge Voltage |

2000V |

|

|

Static Ionizing Time |

below 0.5 sec |

|

|

Ion Balance |

below ± 10V |

|

|

Air Pressure Range |

0.05~0.5 MPa |

|

|

Air Flow |

below max 300 L/min |

|

|

Air Flow Type |

Air: Dried Clean Air |

|

|

Perss-Key Mode |

Switch Mode CONT / Press 1 (0.05s On)/ Press 2 (0.01s On) |

|

|

LED Mode |

Swicth on-off Mode ON(Always)/ SYNC(Shooting)/ OFF(Always) |

|

|

Running Temp, Moisture |

0~+50℃, 30~65% |

|

Feature |

Application Fields |

|

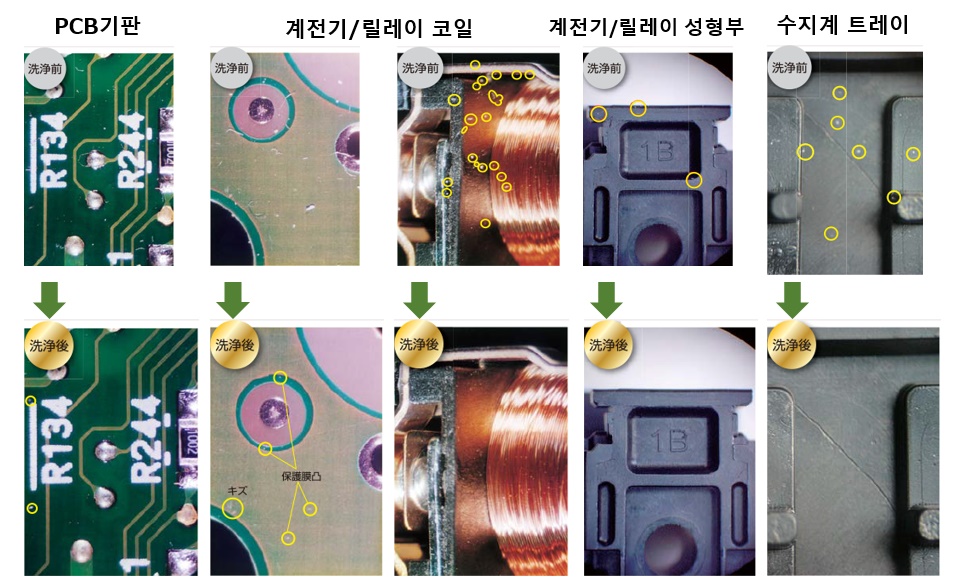

Air-GAir-Gun type quick cleaning unit HPG-7000 models.You can clean the air with ion air blowers. electrostatic removal. |

|

|

Application |

|

|

Kinds of PCB board, Remove dust before assembling electronic components.Anti-static, stabilizing,Tray making, packaging process for semiconductor parts,and electronic components, Glass, Wafer, Chip, Film Production, Packaging Process, etc. |

|

|

Installed Buyers |

|

|

Fuji Electric, Hyundai-Mobis, Jawhua-Electronics, Panasonic, Omron, Murata-Machine etc. |